Smooth operations in today’s busy business world depend on effective maintenance management. Companies now depend on both Computerized Maintenance Management Systems (CMMS) and Work Order Management Software to improve this important area. Mainly, these digital solutions help save time during maintenance, avoid delays and ensure assets are reliable. Yet, there are differences between CMMS solutions.

Here, I’ll show you the main features you should look for in a CMMS, so you know exactly which system your business needs.

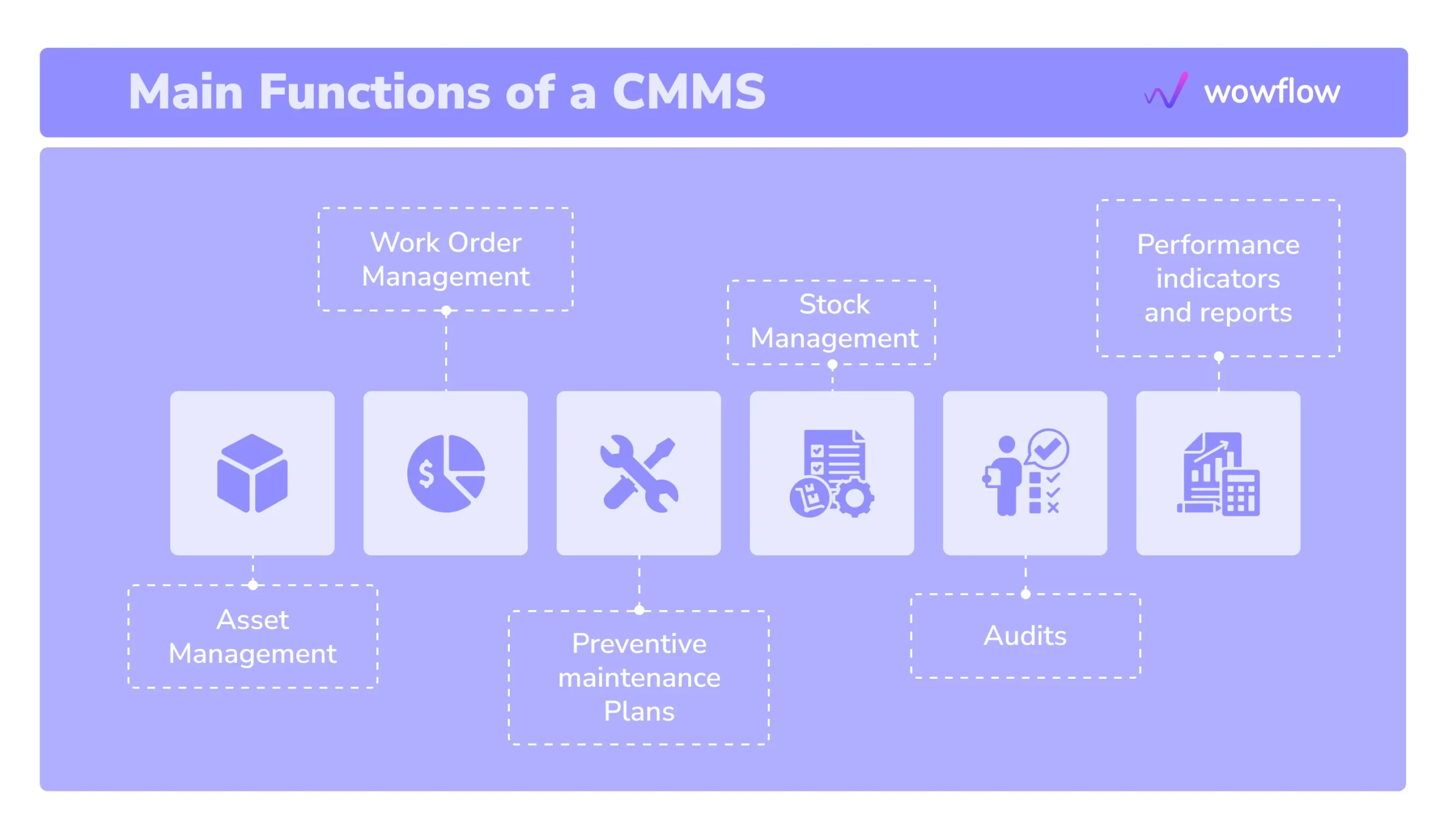

Your CMMS should handle the monitoring of assets, allow for maintenance before problems occur, handle all supplies and assist with assigning and following up on work orders. It should be simple for anyone to use and link with IoT, enabling immediate monitoring. In particular, an efficient performance management system allows us to understand which maintenance processes are the most effective and how resources should be allocated, helping us improve all the time.

1. User-Friendly Interface

A CMMS should be available for both technicians and managers. An interface that is straightforward allows everyone to get used to the software faster, boosting everyone’s productivity. Make sure that the CMMS options you check can help with simple dashboards, are not too complicated to use and have tools that work for your organization.

2. Work Order Management

Strong Work Order Management forms the foundation of any CMMS. This capability should let you generate, manage and track your work orders effortlessly. With a good CMMS, you should be able to prioritize your tasks, schedule work and track the project’s progress continuously. It achieves efficiency in operation and fair resource distribution.

3. Preventive Maintenance Scheduling

Having your equipment checked and serviced regularly helps them last longer and avoid sudden failures. It’s important for a CMMS to provide strong tools for planning and handling preventive maintenance assignments. As a result, machines will be reminded to check routine inspections, service equipment and fix parts based on how much they’re used. If you fix up your machinery before it breaks, you won’t experience lengthy downtimes.

4. Inventory and Asset Management

Every effective CMMS is designed to include both inventory and asset management. You should be able to keep track of your spare parts, materials and equipment right now with these modules. It is important that you handle stock replenishment, fully stock your warehouse and assign inventory data to necessary work orders without complication. By integrating, Parts Trucks help technicians keep things on track by having the necessary parts when they are needed.

5. Reporting and Analytics

To base your work decisions on data, your CMMS needs to include detailed reporting and analytics. To improve your maintenance approach, you need detailed reports about the performance of your assets, regular maintenance activity and work order history. A CMMS with adjustable reports, trend analysis and visual tools should help you learn more about your maintenance operations.

Conclusion

This way, an effective CMMS or Work Order Management Software must feature a friendly user interface, solid work order handling, preventive task processing, management of assets and inventories and advanced analytics reporting. Using these techniques in your plan can improve performance, cut back on downtime and allow you to save time and money. As you select a CMMS for your company, look carefully at these features to guarantee your investment is wise. A CMMS that includes these features can greatly improve your maintenance procedures in any industry.